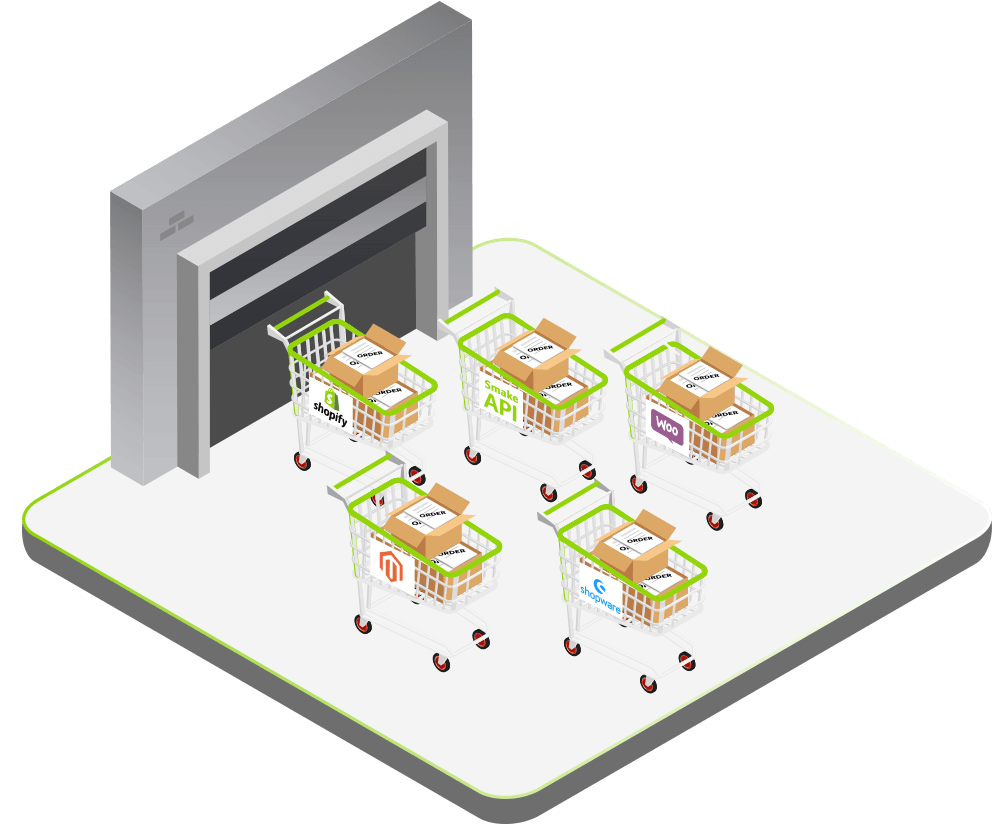

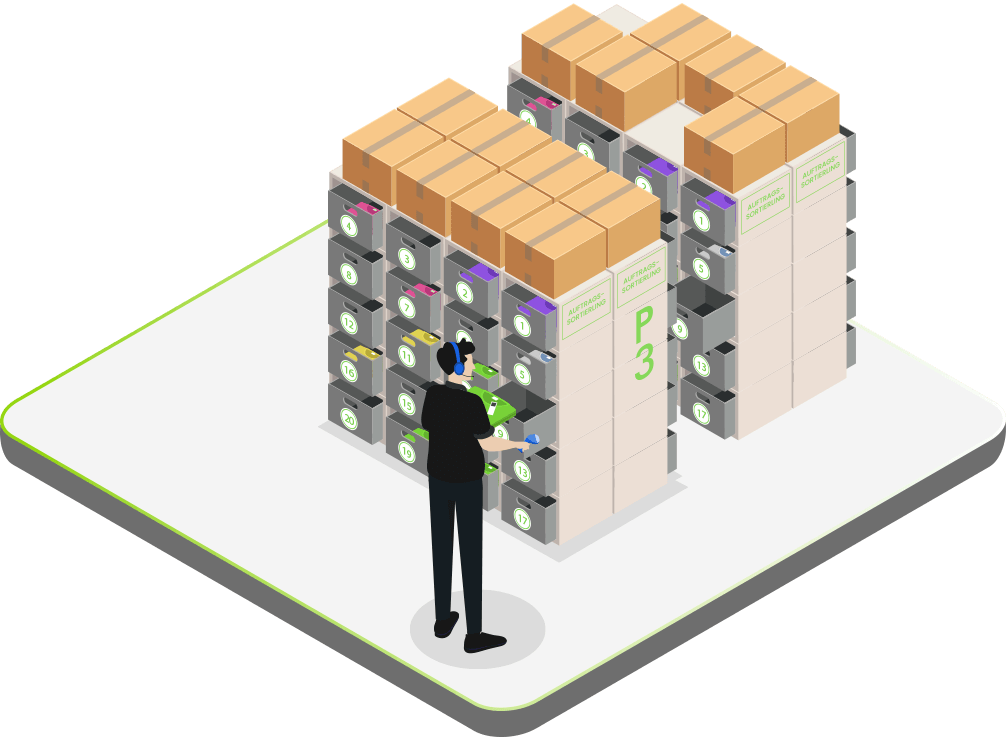

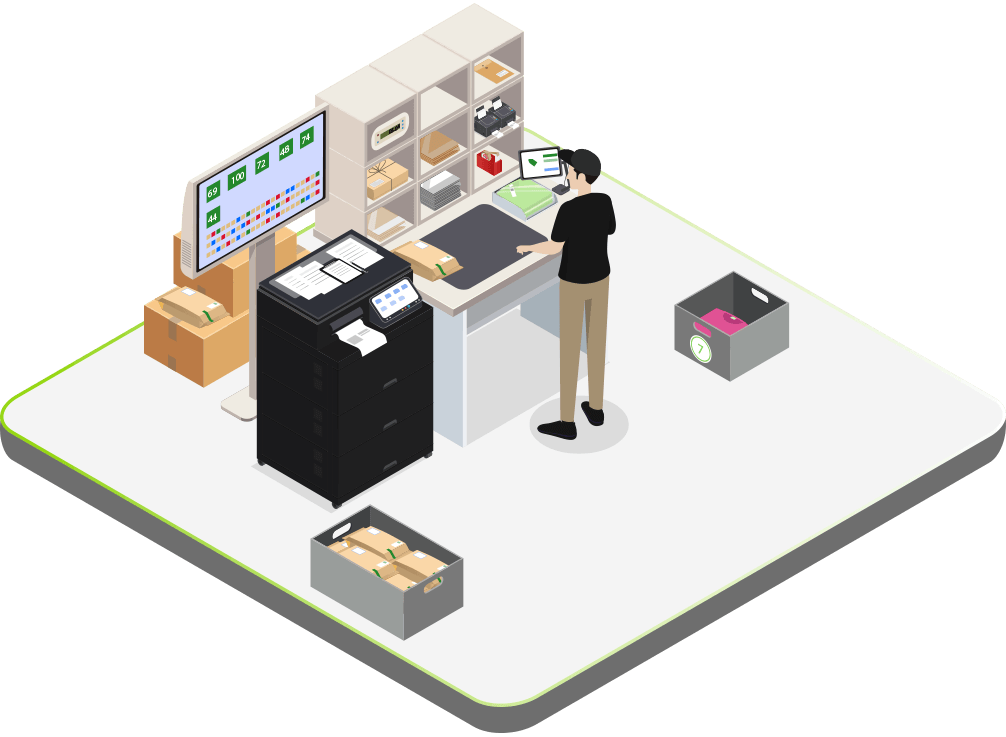

c INTEGRATION OPPORTUNITIES

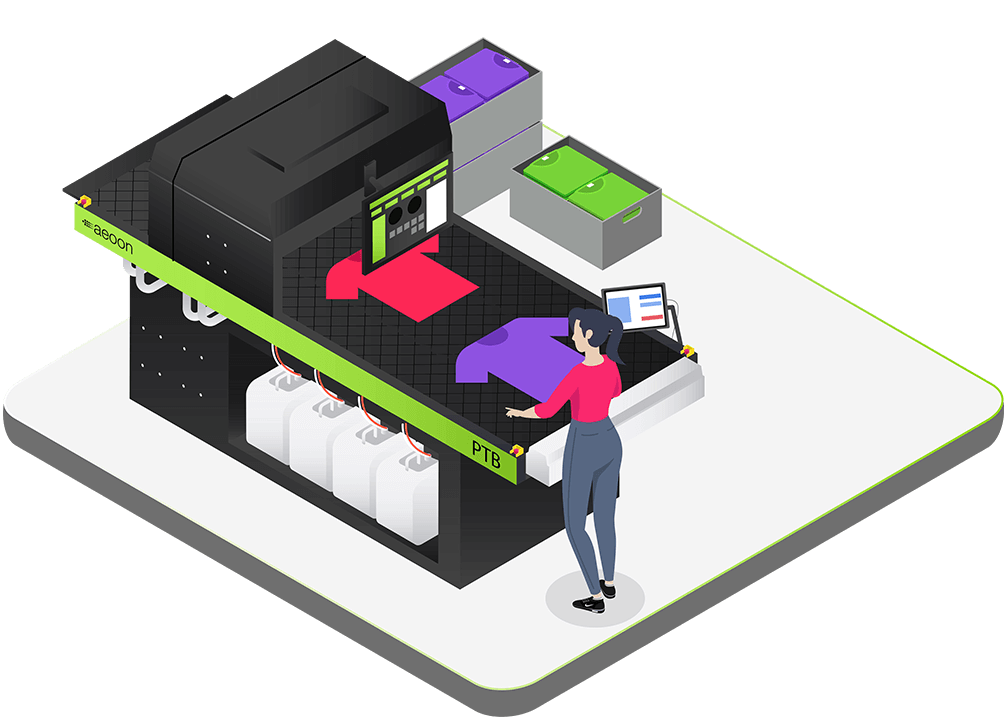

] NEED A SMALLER SOLUTION?

RESTful API

Print and send products with a simple API request. After the integration, you can get started right away and take advantage of all the features, including white label shipping and order/dispatch verification.